In logistics, streamlining efficiency and increasing the visibility of operations are crucial to achieving success in the supply chain. Yard management is how your company transports workers, cargo, pallets, trucks, cars, and other items from the yard to ports.

Effective yard management is vital in ensuring the proper flow of freight between the incoming and leaving points. Yard Management Software (YMS) is among the most crucial tools for this process and is transforming how companies run their lawn operations.

Companies have moved away from traditional yard management methods over the last few years. These conventional methods were usually manual and heavily dependent on paper and physical oversight. Modern YMS is not just a way to track docks and trucks or schedule dock appointment times and appointments but also offers an entire process for streamlining and enhancing yard operations to improve the efficiency of the supply chain. The global Dock and Yard Management System software market was estimated to be over $4.5B in 2022. This market size is projected to grow to $7.3B in 2026.

Modern technology permits more efficient, sophisticated operations and greater visibility, so your warehouses could become profit-making machines. Automating warehouse systems (WMS) can improve the accuracy of your orders, speed, and time to delivery while decreasing your labor costs by thousands of hours.

Let’s examine how a yard management system software can transform the usual issues yard managers face into opportunities for companies to flourish in a competitive market.

What is a Yard Management System?

Yard-management systems were created to help and manage the transport of trailers, trucks, pallets, workers’ yards, warehouses, and workers to load and unload new and existing commodities properly. Due to the faster turnaround times required by modern supply chains, efficiency is more crucial than ever.

Yard operations must be better visible and controlled with the help of yard management system software. This way, you can increase the flow of goods in and out of the country while cutting expenses and addressing increasing customer requirements.

The ability to provide warehouse workers with real-time information regarding yard activities and the locations of trolleys, trucks, and other equipment within and on the warehouse floor will make yard management easier. This system will also allow for easy access to pallets and other items in the yard, ensuring overall efficiency.

Benefits Of Investing In Yard Management System Software

Yard management software offers many positive benefits for companies who want to improve logistics and supply chain processes. Here are the main reasons yards management software is a must:

1. Visibility in real-time and efficiency of workflow

Imagine coordinating a massive but uncontrolled flow of trucks and trailers in a vast warehouse and trying to reduce the loss of time. In the absence of real-time monitoring, it is similar to driving with your eyes closed. It’s impossible to predict the moment you’ll crash into something. The yard management system software can eliminate the blindfold. With the latest YMS software, companies can get an expansive view of yard operations and track every step. This is especially important in highly-volume settings where even a tiny error or delay could lead to significant interruptions.

The day’s yard inspections were performed with walkie-talkies and clipboards or when teams were required to hold several meetings to communicate information about status updates. Modern YMS software can integrate seamlessly with existing systems such as ERP or the WMS (Warehouse Management System), which ensures flawless coordination and a simple exchange of information. The significant change in YMS has shifted to cloud-based, web-based systems. These platforms allow users immediate data access, regardless of location.

2. Automation: From check-in until checkout

When handled by hand, yard management can be complicated, time-consuming, and costly. Every logistics professional knows the possibility of running into a bottleneck due to a missed appointment or lost paper. Automation has revolutionized yard operations, providing unparalleled efficiency and accuracy.

An excellent example of this is the process of checking in trucks. Traditional systems require manual truck entry at the gates and physical verification of documents. When you use an automatic YMS check-in process, it is much faster and easier. When YMS is paired with technology like RFID or barcode scanners, automated gate access is made feasible, drastically cutting wait times while providing smoother movements within the yard.

Furthermore, YMS can send notifications of any actions to warehouse supervisors. Imagine being immediately informed of an early truck’s arrival or delay. These notifications facilitate planning changes and proactive decision-making in real time. Managers do not have to fumble in the dark. They have data at their fingertips.

3. Reducing the inefficiency of warehousing and bottlenecks

Inefficiencies at warehouses can rapidly escalate into significant supply chain costs regardless of whether it’s a vehicle idle for too long waiting for clearance or an unplanned delivery time due to poorly managed schedules.

One of the leading causes of inefficiency is bottlenecks. Many things, such as unexpected vehicle breakdowns, a lack of communication, or a lack of real-time information, can cause these bottlenecks. Modern YMS provides KPIs and metrics to aid in identifying bottlenecks within yard operations. Utilizing this data, logisticians can make educated decisions to redistribute resources and increase throughput.

4. Improved dock management and control of distribution centers

An essential aspect of YMS is the dock door allocation. A well-functioning YMS uses heuristics to assign dock doors according to multiple elements like the type of shipment urgency, the type of shipment, and resources, thus ensuring smooth yard operations.

However, YMS does not function as a stand-alone system. In particular, integrating YMS with WMS ensures that inventory data, order information, Warehouse workforce data, and shipping specifications are in the same place. This integration removes information gaps, allowing smooth operations from the yard through the docks and finally into the distribution center.

5. Inbound and Outbound optimization

Outbound and inbound operations are the lifeblood of every distribution center. A well-designed YMS can handle these as an efficient machine. Inbound activities are managed by the YMS, ensuring that all inbound shipments from suppliers and distribution centers are identified, assigned dock doors, and handled effectively. This is why the Software for managing the yard connects perfectly with the Transportation Management System (TMS) to ensure that the incoming shipment is aligned with the yard’s capacities and capacities.

On the other hand, outbound activities include the delivery of inventory or finished goods to retailers, customers, and other centers for distribution. This requires seamless interplay with the YMS and the warehouse management systems (WMS).

For example, when the WMS informs the YMS that an order is ready to be dispatched, The YMS will schedule the truck to deliver that order. This kind of integrated operation ensures on-time delivery and happy customers. In both outbound and inbound situations, The YMS serves as an intermediary, making sure that there aren’t any data silos.

6. Integration and scaling capabilities

Today, businesses require solutions that adapt to their needs. Traditional systems are often unsustainable when businesses grow. That’s why they are in the Software as a Service (SaaS) model, which modern yard management companies use to play an essential role.

A cloud-based YMS has unique scalability. If a company is planning to expand, establish an entirely new distribution center, or respond to seasonal fluctuations, a SaaS-based YMS ensures that yard management processes can grow rapidly.

In addition, the flexibility of the current yard management tools on-site cannot be overstated. Every yard or dock door and each gate management process could have distinct nuances. Contemporary YMS software, which is web-based and adaptable, ensures that the individual needs of each site can be met, allowing an individual solution to be designed to meet the unique requirements of each property.

7. Robust KPIs and metrics monitoring

You cannot manage what you cannot measure. This is especially true for the yards. KPIs and metrics (Key Performance Indicators) are similar to business compasses that guide shippers, logisticians, and distributors through various supply chain challenges.

Modern yard management system software give you a detailed view of yard activities and KPIs. From check-in times to dock door closures to average wait times, the KPIs drawn from these metrics provide an enthralling picture of the yard’s performance.

Yard management software can be discussion anchors based on data for warehouses. The vast amount of data gathered from YMS can assist in the development of patterns. This helps managers make informed decisions, as the data now supports these decisions. This can save top management lots of time and help ensure that yard operations are in top form.

8. Improved the management of warehouse assets and inventory

Yard management doesn’t only involve managing the movement of trucks and trailers. It’s also associated with the management of inventory. In the end, what’s inside these trailers can be just as important as the movement itself. A seamless connection between the yard and the inventory will ensure that the goods arrive at the appropriate port door on time, at the proper time, and in perfect condition.

This increased visibility also benefits inventory management within the yard. By utilizing RFID tags, barcode scanners, and other advanced tracking methods, the YMS offers real-time updates of the inventory status. The integrations will ensure that the status is always clear regardless of whether it’s a perishable item in a refrigerator or high-value electronics stored in an enclosed container.

Yard management software can boost the overall maturity of supply chains when combined with inventory management, warehouse asset tracking TMS, and various other advanced capabilities, making it a vital part of the bigger supply chain machine.

How to Implement a System for Yard Management in Logistics and Supply Chain

The modern wave of the digital revolution has transformed every sector, and the supply and logistics industries are no exception. Yard management software development has rapidly transformed businesses as many realize the advantages they can provide and choose to incorporate these revolutionary techniques into their processes. This is a step-by-step procedure for integration into a yard management system software:

1. Assess Your Current Yard Operations

The initial step to a YMS installation is to review your yard’s operations thoroughly. This requires understanding yard workers’ existing processes, workflow bottlenecks, and daily problems. When you conduct a thorough study, it is possible to identify areas where a YMS could bring about the most significant improvement. Common problems that a YMS could address are inefficient trailer movements, wasting time looking for assets (trailers containers, tractors, trailers such as tractors, containers, and trailers), lengthy wait times to load and unload, insufficient space utilization, and inadequate access to yard activities.

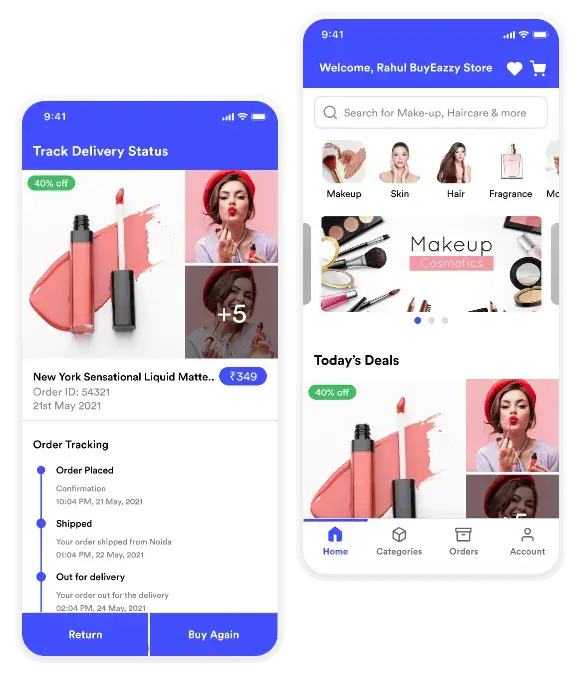

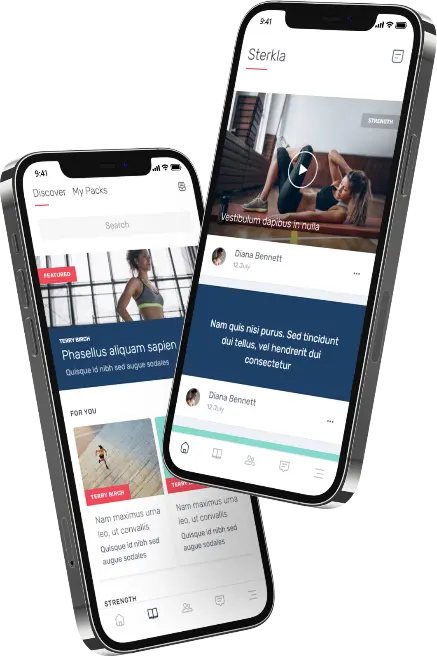

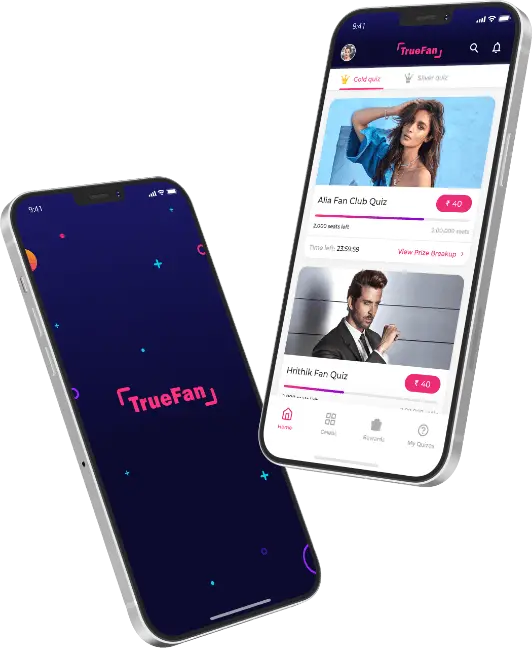

2. Reliable App Development Partner

The most important step is working with a trusted mobile app development company in USA for developing logistics and supply chain software. So, do extensive research and search for an established development team with an established track record of providing industry-leading solutions. A seasoned tech partner will quickly identify your needs and provide the desired results.

3. Research and Gather Requirements

You must thoroughly analyze the yard’s operations to determine inefficiencies and identify the most important needs. It is possible to involve stakeholders to ensure that the system addresses the most pressing issues, including real-time tracking, inventory management, and asset management. In this phase, your development team will outline the yard management software development and implementation.

4. Develop Software for Yard Management

The next step in managing your yard is to develop and design a customized yard management solution for your supply chain that matches your company’s objectives. Although you could also select an off-the-shelf product, choosing a customized system is always better. It lets you address your unique operational issues, seamlessly integrate with your existing systems, and expand as your business expands. Additionally, a customized YMS solution allows you to make the most of features such as gate management, task scheduling, and analytics for optimal performance.

5. Integration with Existing Business Systems

Integrating YMS with business systems to improve the supply chain and logistics is the most important yard management process flow. The most common tools and platforms used that are suitable for YMS integrations are:

- Enterprise Resource Planning (ERP) Systems

- Warehouse Management Systems (WMS)

- Transportation Management Systems (TMS)

- Labor Management System (LMS)

- Fleet Management Software

- IoT and GPS Tracking Tools

- Barcode and RFID Systems

- Electronic Data Interchange

6. Testing and Team Training

Test the system thoroughly to determine and address any issues before deploying. Perform pilot runs and collect feedback to improve features. Also, give your employees complete training on using the Software to be proficient in using the new system.

7. Maintenance and Support

After the complete deployment, monitoring your system and implementing maintenance strategies is important to ensure continuous performance and effectiveness for your YMS. Monitoring performance, frequent maintenance, and updates help solve issues swiftly and align your system to your business’s changing needs.

Use Cases of Yard Management Software in Logistics and Supply Chain

Yard management software development is important in optimizing logistics and supply chain processes. The significance of an YMS extends far beyond just operational enhancements; it assists in meeting customers’ increasing demands for quicker delivery and smooth operation. Let’s explore yard management software’s myriad applications and potential for transformation.

1. Automated Appointments Scheduling

Yard management software facilitates the scheduling process by allowing shipping companies to book slots via a centralized system. This prevents communication issues that cause overbooking and ensures that appointments align with availability at the dock and in the yard.

2. Gate Management

With automated gate check-ins and outs, YMS optimizes entry and exit procedures. By utilizing technologies such as RFID, GPS, BLE, and QR codes, YMS allows for faster communication between drivers and dock staff to reduce wait times and increase vehicle efficiency.

3. Dock Scheduling and Management

YMS plays an important role in organizing and managing dock doors. This helps ensure trailers are quickly allocated to the right dock to load and unload. It also helps reduce delays, congestion, and idle times for drivers and equipment. By optimizing dock utilization, companies can increase productivity and handle a greater volume of deliveries.

4. Inventory Management

YMS utilizes the latest technology to offer real-time tracking of yard inventory, including containers, trailers, and other equipment. Yard managers can precisely monitor and control inventory levels and ensure that the equipment is in stock when required. This helps avoid stockouts and operations delays, maximizes resource use, and keeps the supply chain on track.

5. Task Allocation

Spotters are crucial for efficiently moving trailers and containers around the yard. YMS alerts spotters whenever docks become available and quickly assigns tasks to move trailers to the designated dock doors. This helps reduce idle time, increase time to market, and provide smooth trailer placement to load or unload the trailers.

Best Practices for YMS Implementation

To successfully integrate YMS into your business’s operations, you must take several essential steps to improve yard operations efficiently.

1. Initial Assessment

Begin by thoroughly reviewing your current yard operation. In your assessment, it is important to pinpoint operational inefficiencies, pain points, and other areas in need of improvement. This initial evaluation will assist you in defining the requirements specific to your business and the essential features of your YMS by addressing your business’s specific issues and working towards your specific objectives in the operational area.

2. Customization

Adapting the YMS to meet your specific needs as a business is another vital step. While developing, you will collaborate with your software vendor to design the new system in line with your existing workflows and processes. This could include establishing schedule scheduling, gate control, and tracking systems that satisfy your needs. Installing a YMS could result in a noticeable improvement in productivity across your yard.

3. Training

To ensure the success of YMS deployment, you need to provide regular training to your employees. You must ensure that yard employees, office staff, dispatchers, and drivers are comfortable working with the latest system. Proper training helps reduce resistance to change and increases the system’s advantages, allowing employees to take advantage of all features efficiently from the beginning.

4. Invest in Reliable Technology

Choosing the best YMS technology is crucial to the success of the implementation. Look for a YMS that is compatible with your business’s particular requirements and works well with the existing system. Consider features like the ability to schedule appointments dynamically and digital check-in, real-time transparency, and automated data capture analysis and reporting.

A reliable technology will ensure the efficient and efficient tracking of inventory and yard operations and a data-driven approach to decision-making. When evaluating YMS vendors, consider factors like their industry experience, customer reviews, and track record of successful implementations. Discusses with vendors to better understand their support, flexibility, and customization options.

5. Streamline Communication

Communication is essential for a smooth yard operation. Establish a central communications process within YMS to enable real-time communication between yard managers, truck drivers, and other key stakeholders. Automated notifications, alerts, and electronic documents will help reduce mistakes, delays, and confusion.

By streamlining communication, the YMS reduces dependence on manual methods of communication, such as phone calls or paper-based documents. This reduces errors, boosts efficiency, and increases overall operational visibility.

6. Optimize Yard Layout and Traffic Flow

An efficient yard layout and circulation are crucial to maximising storage capacity and reducing handling time. Create specific areas in the yard for various types of wood and clearly mark them. Implement strategies for traffic management to minimize congestion and allow for the smoother moving of equipment and trucks.

Use the YMS to monitor yard occupancy, assign parking spaces, and improve load sequence. This will allow for efficient use of space and decrease time spent looking for inventory. Automated workflows in the YMS can assist in prioritizing assignments, assigning resources, and optimizing routing for greater efficiency.

7. Utilize Data Analytics

Use the data analytics provided by YMS to gain useful insight into yard operations. Examine historical data to find patterns, bottlenecks, and areas for improvement. Use data visualization tools to present data in an easy-to-follow and practical way.

The YMS can produce reports and analyses on various aspects, including inventory accuracy, truck utilization, and yard congestion. These data can be used to improve workflows, make informed decisions, and create constant process improvement.

Top Yard Management Software (YMS) Trends to Watch for 2025

The Software for managing yards (YMS) market is changing quickly as supply chain operations face increasing requirements for automation, visibility, and efficiencies. As we move into 2025, a number of key trends are expected to change the way that yard management system software aid operations, reduce costs, and help ensure sustainable development. Let’s look at these trends that will shape the future of Software for yard management.

1. Advanced Automation and Robotics Integration

Automation technology is changing the processes for managing yards. Many businesses now utilize automation to cut operating costs and increase yard efficiency. AGVs (automated guided vehicles) (AGVs) and drones are being used more frequently to ease the movement of facilities, drastically reducing human error and speeding up loading and unloading. In 2025, these systems will play a significant role in yard management, eliminating delays and inefficiencies.

2. Predictive Analytics and Data-Driven Decision-Making

Predictive analytics is transforming yard management by enabling data-driven decision-making. YMS platforms today use machine learning to anticipate activity peak times, determine the need for maintenance, and predict interruptions. Logistics managers can adapt their plans and resources, which in turn helps cut downtime and demurrage costs.

Predictive analytics can be particularly advantageous for large businesses, where efficiency and cost savings are vital. By anticipating future needs and addressing potential problems, YMS can help facilities keep their operations running smoothly. This is crucial to addressing customers’ growing demands for speedy shipping and reliable service.

3. Enhanced Sustainability Initiatives

Sustainability is now a key aspect of yard maintenance as businesses attempt to reduce their environmental footprint. YMS platforms are designed to support eco-friendly practices by reducing idle time and fuel use. For instance, intelligent scheduling in YMS can help mitigate unnecessary trailer movements, which reduces fuel use and emissions. By promoting efficient yards, YMS contributes to broader corporate sustainable goals.

Businesses that use YMS to monitor sustainability indicators will gain an edge in a market that is becoming more eco-conscious. By 2025, sustainability-focused features are expected to be essential for companies seeking to meet regulatory standards and demonstrate environmental responsibility.

4. Omnichannel Yard Management Solutions

The growth of online shopping has brought Omnichannel Logistics to the forefront, and YMS solutions are evolving to meet the demands of. Modern YMS platforms are built to handle B2B and shipping, allowing cross-docking and last-mile delivery to meet shoppers’ demands on the internet. This omnichannel capability enables YMS to handle various shipment types and timeframes, ensuring the efficient processing of online orders and traditional bulk shipments.

YMS systems that can support Omnichannel Logistics will be essential for companies trying to meet consumers’ demands for speedy and adaptable delivery. By optimizing cross-docking and real-time inventory visibility, YMS can assist logistics companies in more efficiently coping with changing times.

5. Artificial Intelligence and Machine Learning

Machine learning and AI are helping to improve YMS capabilities, specifically in optimizing resource allocation and managing trailers. AI-powered YMS can efficiently allocate trailers, anticipate delays, and offer recommendations based on previous data. This is particularly useful for eliminating congestion and improving yard productivity by reducing downtime and minimizing operational delays.

Machine learning is expected to play an important role in detecting anomalies and helping companies spot problems before they get out of hand. AI-powered YMS will also be able to learn from past information to improve operations efficiency, making it an ideal device for facilities that deal with large volumes and require precision yard management.

6. Enhanced Security Features and Cybersecurity Measures

With the increasing digitization of YMS and the integration of IoT technology, cyber security has become more crucial than ever before. Cyber security risks are increasing because yard management system software are becoming connected to cloud platforms and live-time monitoring tools. Enhancing security features like encryption and secure access controls is crucial to safeguarding sensitive information and avoiding interruptions.

Companies that handle goods with value security protocols for cybersecurity within YMS will help avoid costly losses and safeguard assets. Since these applications continue to develop and grow, implementing cybersecurity will be vital for ensuring operation continuity and data security.

Conclusion

Today’s fundamental element of the supply chain is the yard, the crucial intersection that offers many possibilities. In this piece, we’ve explored the power of modern systems for managing yards.

If companies are investing in creating their supply chains as a competitive advantage, switching from manual logbooks and spreadsheets to a more advanced cloud-based YMS could yield the most efficient return on investment any smart move could bring. YMS promises significant efficiency improvements, cost savings, and a competitive edge for the management of supply chains.

Post Views: 842

SA

SA

KW

KW

IE

IE AU

AU UAE

UAE UK

UK USA

USA

CA

CA DE

DE

QA

QA ZA

ZA

BH

BH NL

NL

MU

MU FR

FR